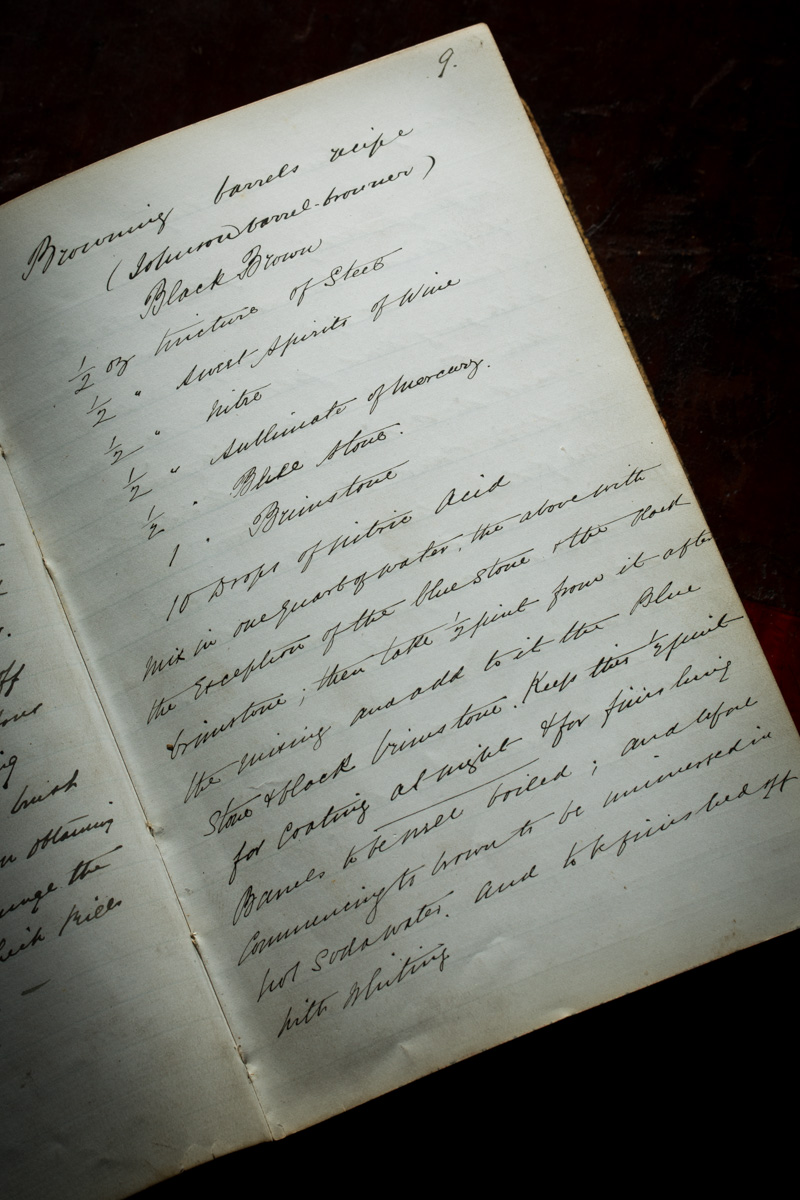

1/2 oz tincture of steel, 1/2 oz sweet spirits of wine, 1/2 oz nitro,1/2 oz sublimate of mercury, 1/2 oz blue stone, 1 oz brimstone (sulfur), 10 drops of nitric acid.

One look at that list of ingredients should answer anybody's question "why can't you do it just like they did it in the old days, the pre war days". A question or statement we all hear, not infrequently.

I would like to assure everyone it is very, very difficult to do a great deal of things related to gunmaking 'nowadays' in a way it was done in the 'old days', perhaps in a way this explains why so few people actually bother!

Many of the chemicals involved with the old finishing process on a gun are now, quite rightly (but annoyingly!), illegal. These chemicals and substances were used in the tinning, blacking, blueing, case colour hardening and stock finishing processes and have had to be substituted by modern equivalents, often less effective substitutes. It is a constant game for the craftsmen working out new processes when they find they can't get a chemical which has been used for a specific task for years.

So I dedicate this 'Leslie Taylor recipe' to all the craftsmen who continually strive to get the very best results, from within ever stricter Health & Safety laws and regulations. To the people who continue to make it possible to make a best gun with a best finish.

And for the person who is not satisfied with the modern day results, the recipe can of course be used in their kitchen, please be careful with the boiling water, mercury/acid combination, and good luck!

Enquire

Enquire

Vance Daigle on December 10, 2014 at 6:45 pm

Thank you Simon for sharing just a small part of what goes into building a Best Gun. With all of it's small nuances and difficulty's of the 21st century that a layman like me would have no clue about. I feel it is through this type of information that I am learning an appreciation for the work that goes into a Westley gun. As my good friend L.D. McCaa tells me as we work to my ordering of a Westley shotgun. It is the sum of all the parts that make it such a great gun. This is just one of many small parts that go into your Fantastic guns. Thank you for sharing.

Neill Clark on December 10, 2014 at 6:59 pm

Fascinating stuff, thanks for the post. It seems almost horrific these days what was used, but it reminds me of when I started my drawing office apprenticeship in 1977. We used Carbon Tetrachloride to wash pencil lines off negatives after inking them, and threw the soaked tissues in the bin. We used methylated spirit to wash the lacquer off the back of a copy negative, and threw the tissues in the bin. And folk smoked in drawing offices, and threw the butts in bin.......there never was a fire but God knows why!

Keep up the posts please Simon.