Most lock patents essentially differed little from the principles of the percussion sidelock, with hammers either on the outside or inside of a lock-plate. Anson & Deeley revolutionised lock design in 1875 and reduced the number of parts dramatically. The A&D requires only a mainspring, a sear spring, a tumbler, a sear and a cocking dog to work.

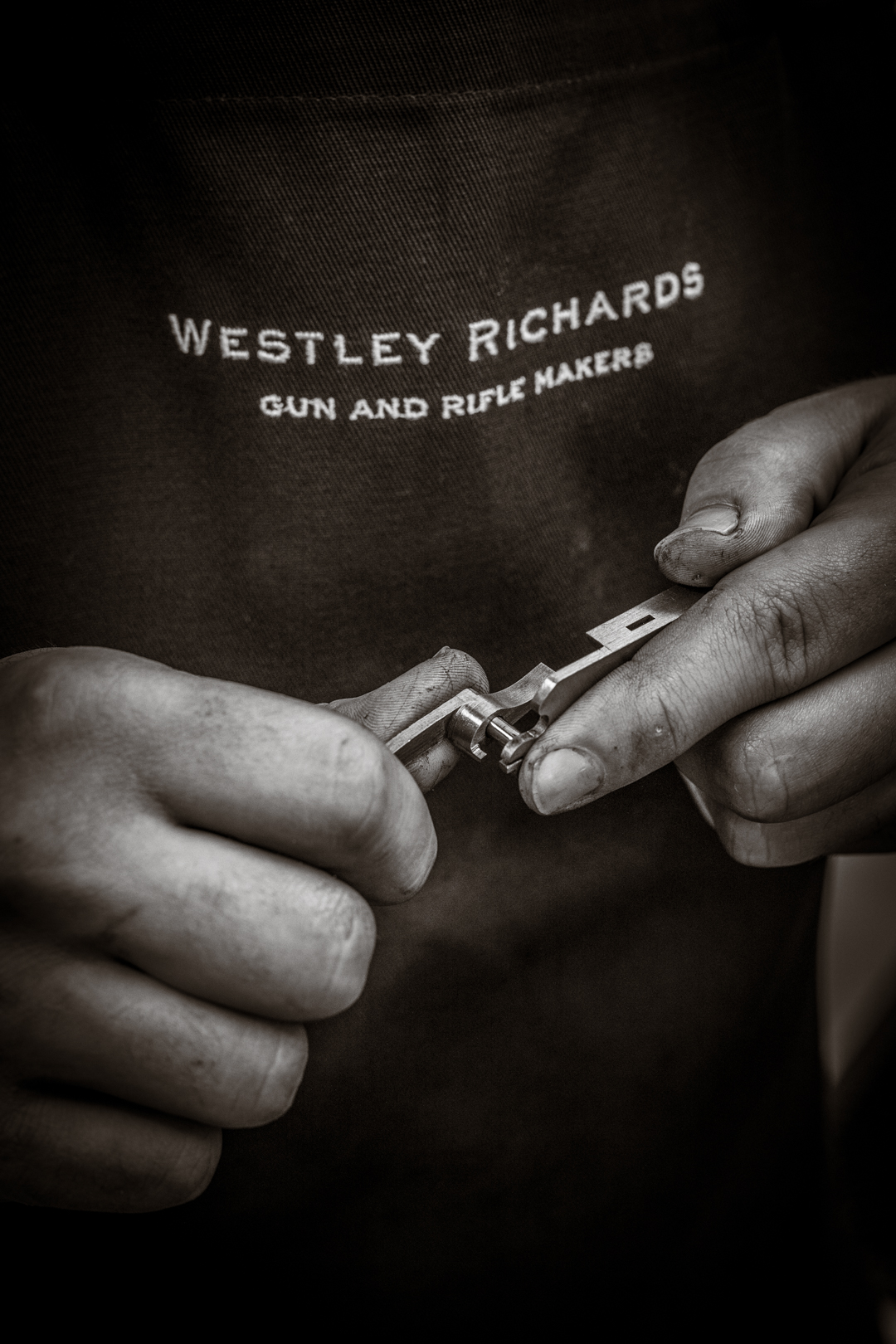

The 1897 introduction of the Taylor patent hand-detachable lock (‘drop-lock’) saw all the main components mounted on a steel plate so they could be inserted into the action via a hinged floor-plate. That system is the same one we still use today to build Westley Richards double rifles and shotguns.

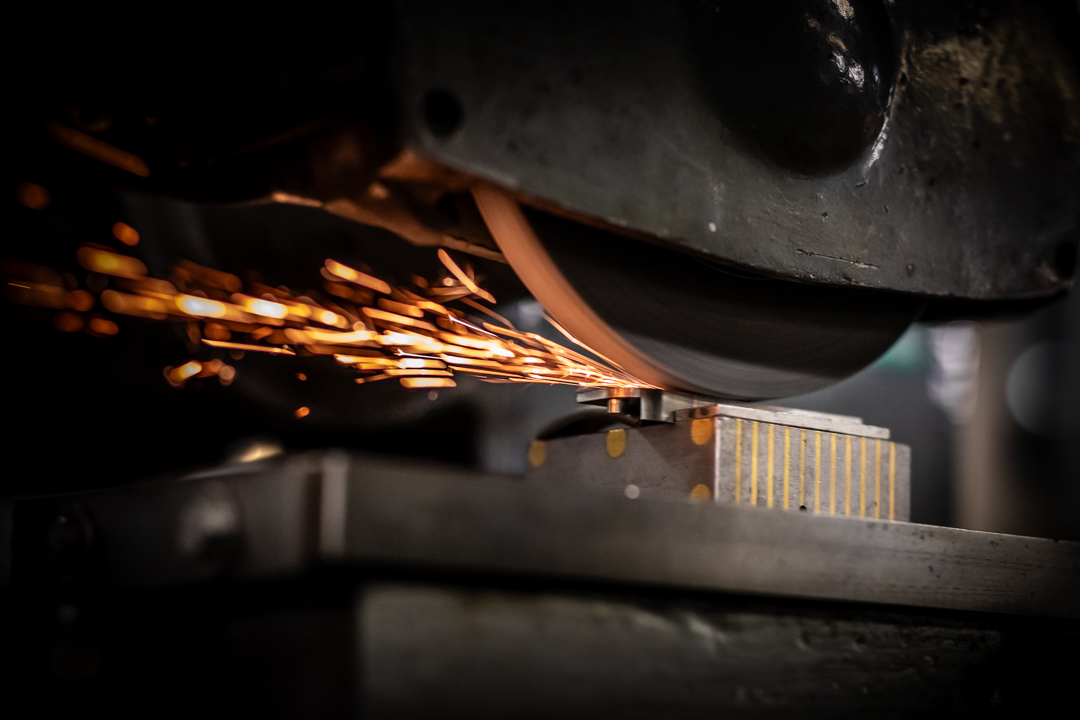

The basic component parts are created at our sister firm Westley Engineering, located in the factory next door. They are delivered to the workshop and there our gunmakers ream, surface-grind and polish them to their final form.

We use a grade of steel called P20 for lock-making due to its toughness. The action body of a shotgun is made from EN32 and double rifles are made from EN36. These are chosen for their durability and their suitability for colour case-hardening.

Our modern springs are made from pre-hardened, spring-steel billet and are wire-cut. We make these springs with a 10% wider splay than the older-style folded steel springs. The extra splay ensures these springs still deliver the same power the old springs used to.

A pair of locks requires twenty hours of a gun-maker’s time to prepare (most of the guns and rifles we make are supplied with two sets of locks). Further work is required at the stage we call ‘connecting-up’, when the locks are fitted to the action and the gun is made to cock, fire and eject. This process normally requires a full day’s work and is very skilled, as every mechanism has to work in a chain-reaction with perfect fluidity.

Our shotguns are made with an integral firing pin on the nose of the tumbler, while double rifles have separate strikers. Shotgun locks, therefore, require more time to fit as the striker nose has to perfectly seat into the striker hole in the face of the action when it falls. Our gunmakers begin to work on locks after around two years’ experience; at first tackling the simpler tasks, then adding the next stage, and the next as they prove mastery of each.

Finally, the locks are hardened and spotted, giving them their distinctive ‘jewelled’ appearance. Once fitted, they can be removed and returned by hand without the need for any tools. Their clever design ensures that it is impossible to re-insert either lock in the wrong side. We completed our last fixed lock Anson & Deeley rifle in 2025 and future orders will be based entirely around the hand-detachable lock.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.

Enquire

Enquire