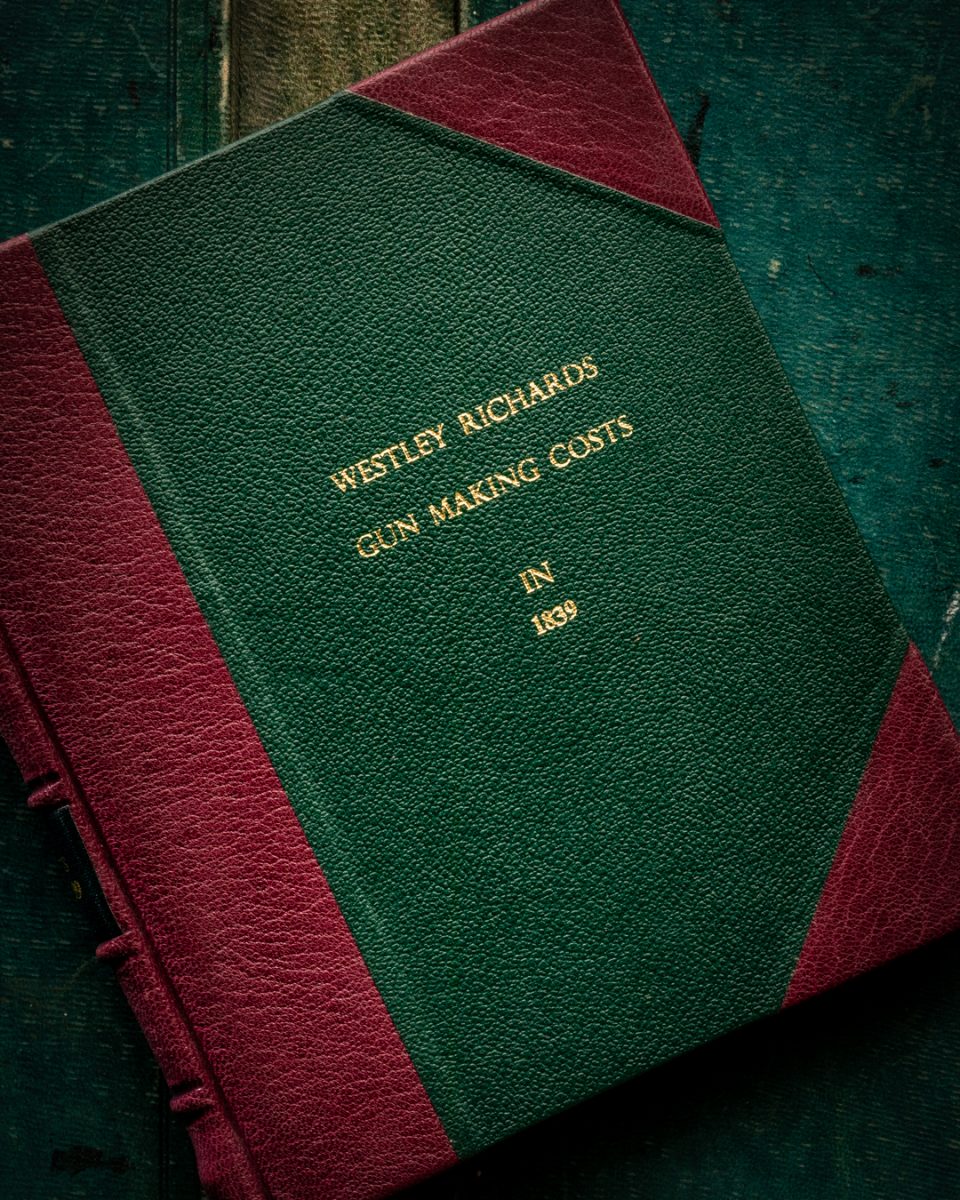

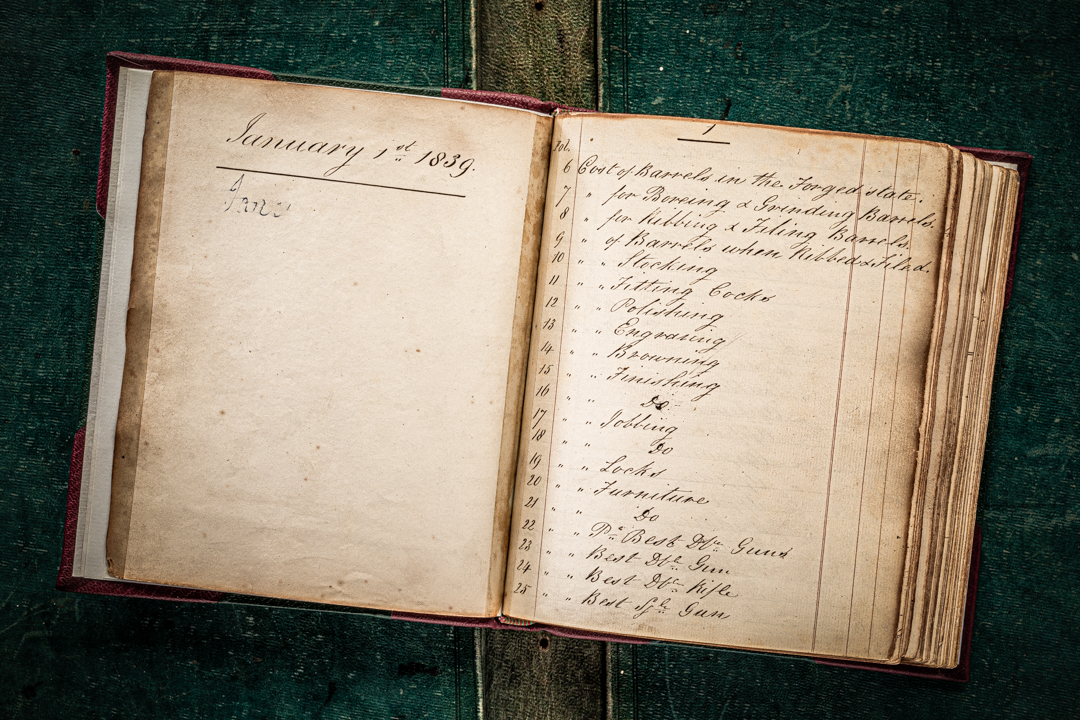

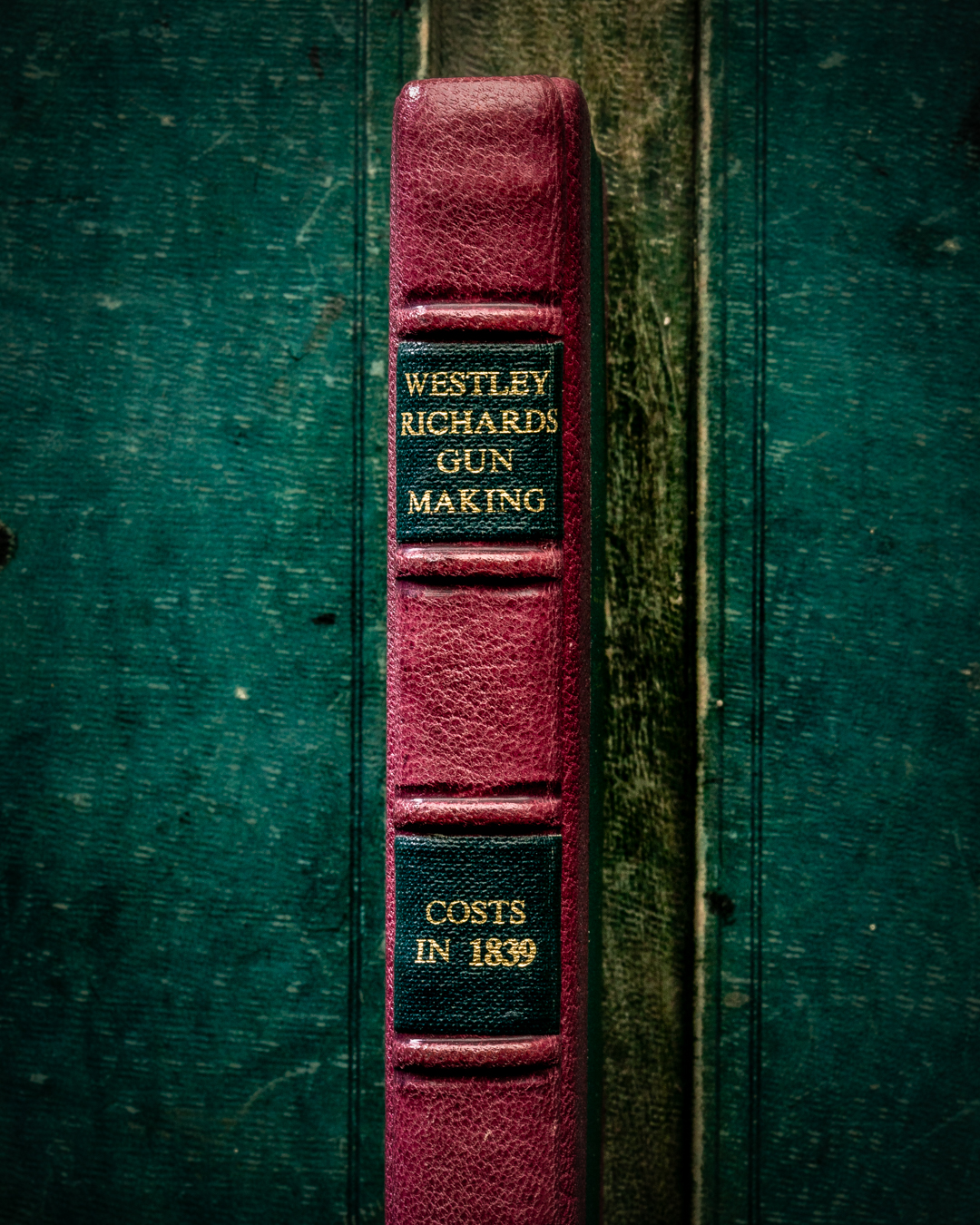

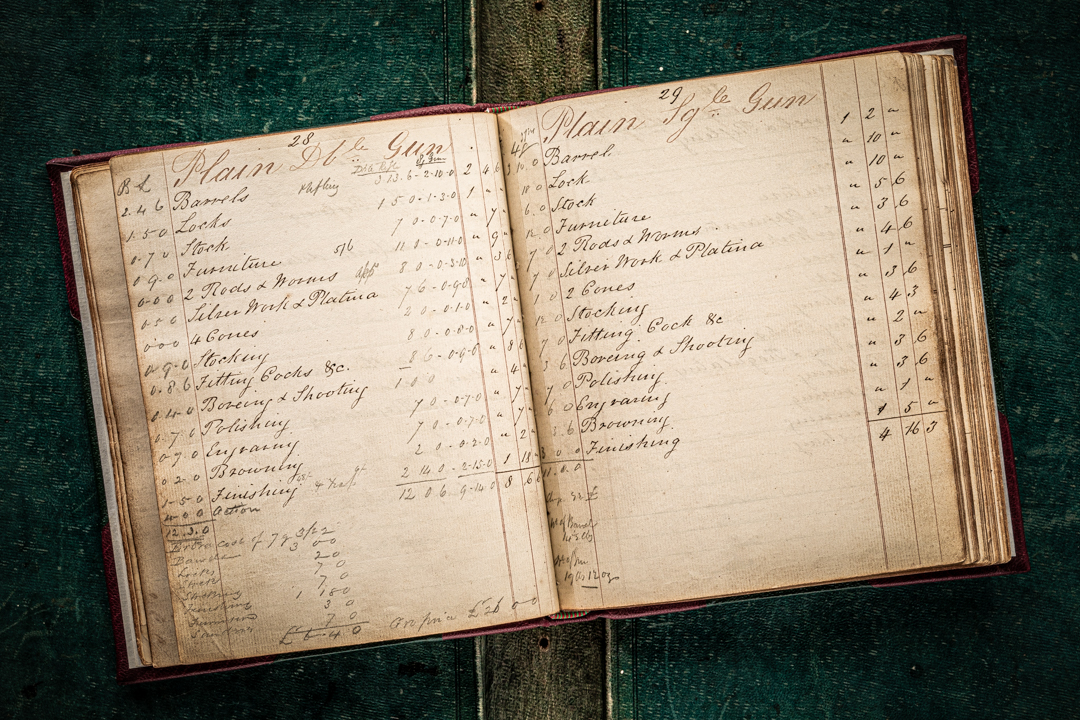

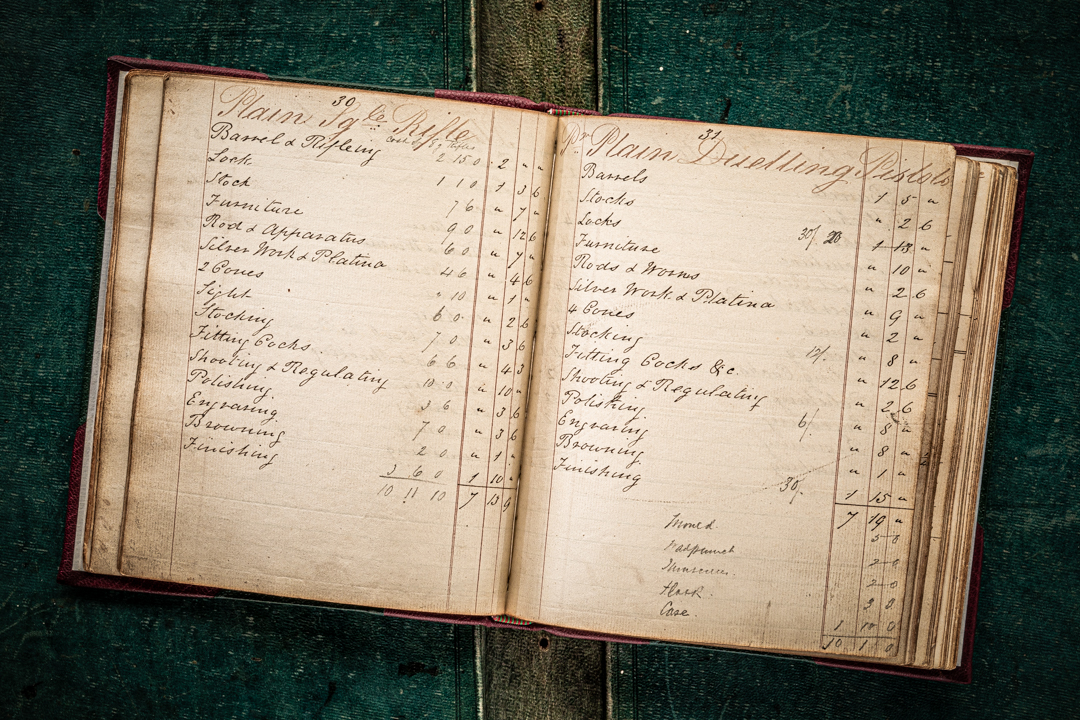

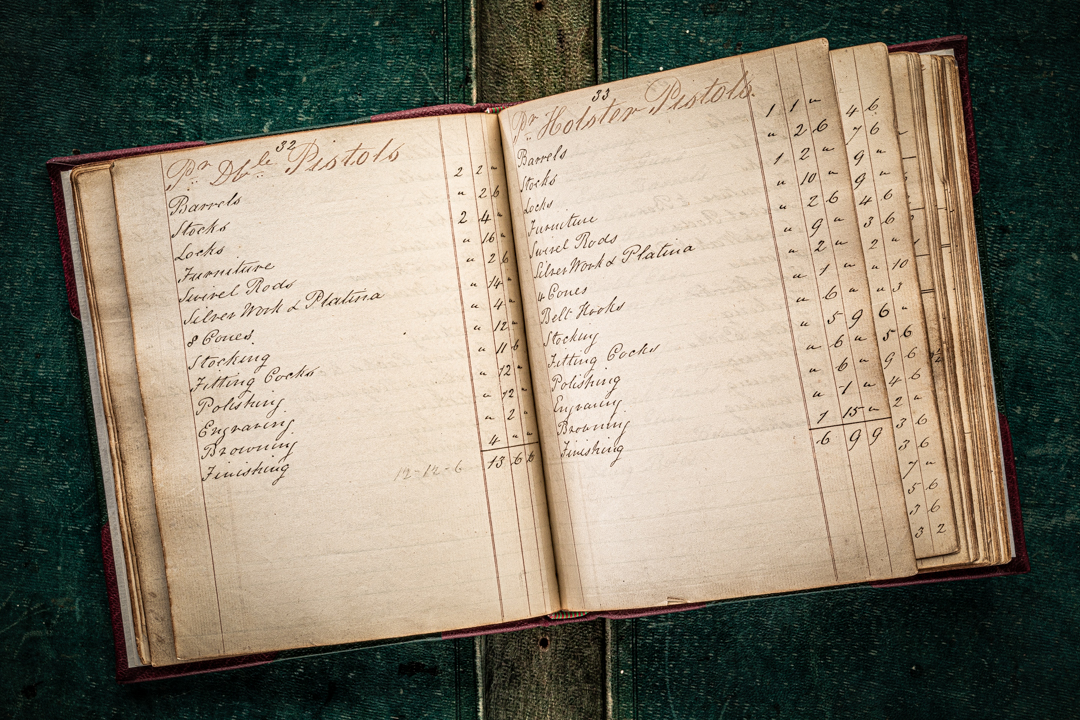

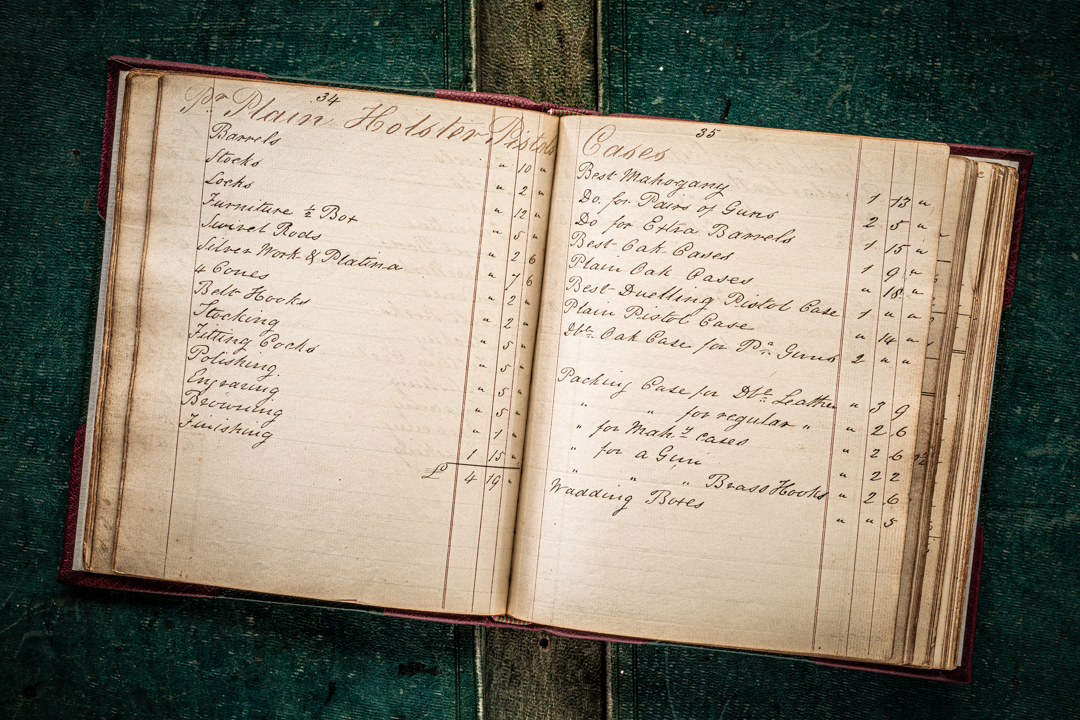

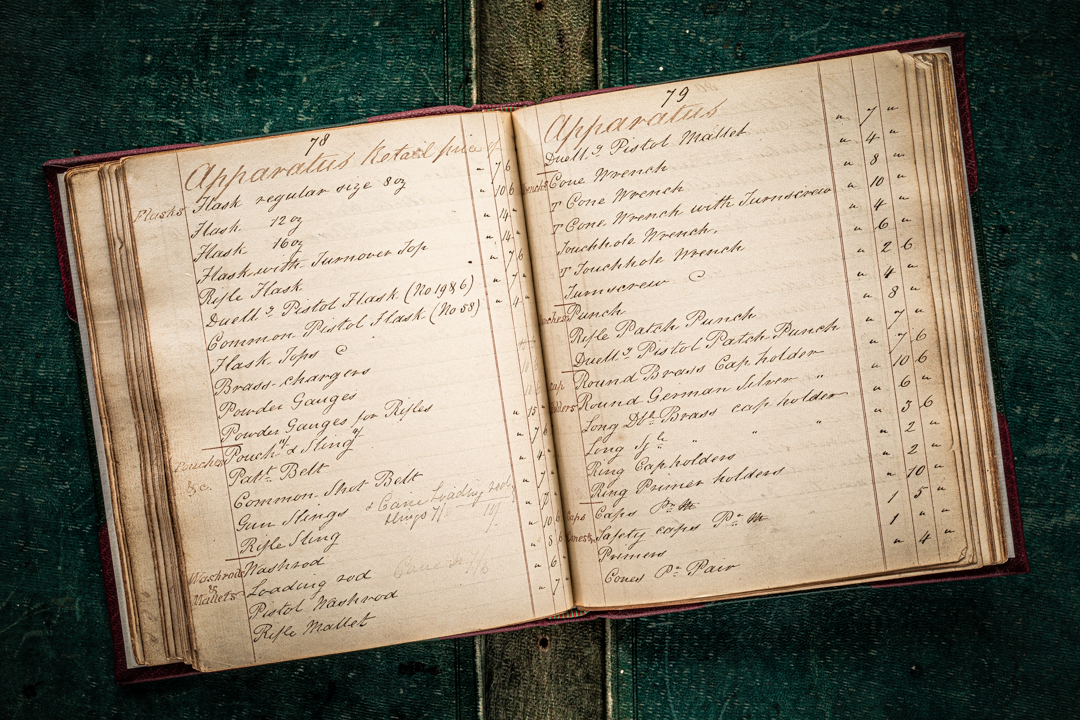

Like its brethren, this book has been beautifully restored and re-bound to preserve its contents for another couple of centuries. Every entry is recorded in beautifully penned script on neatly lined pages with costs in the margin. It begins; 'January 1st 1839....'

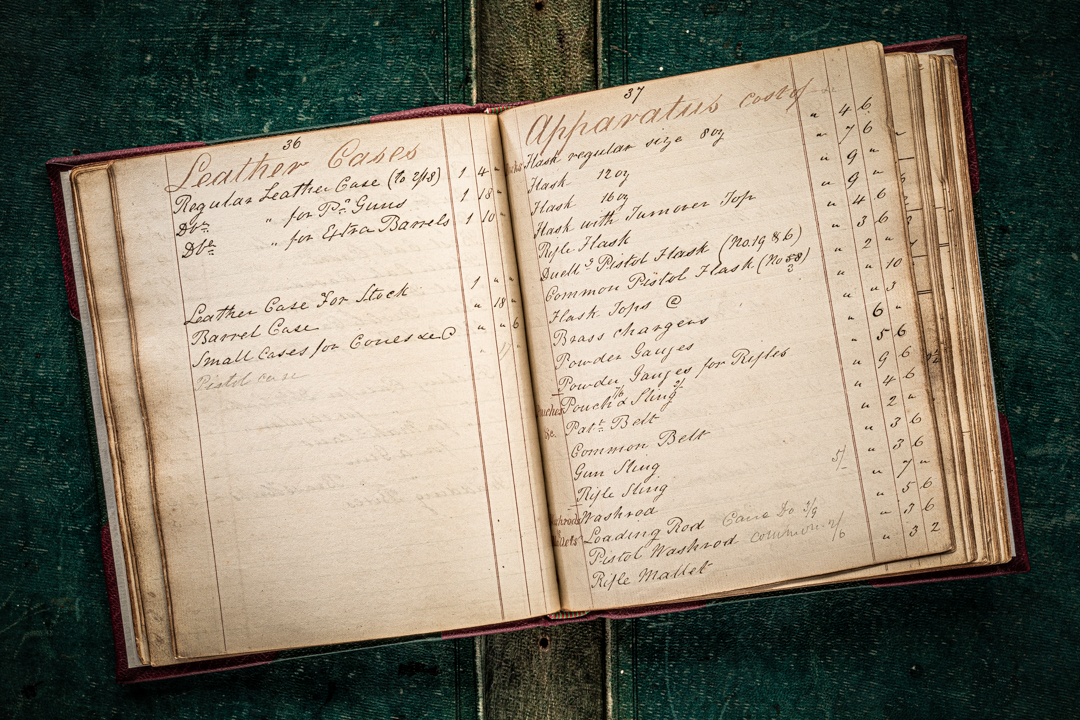

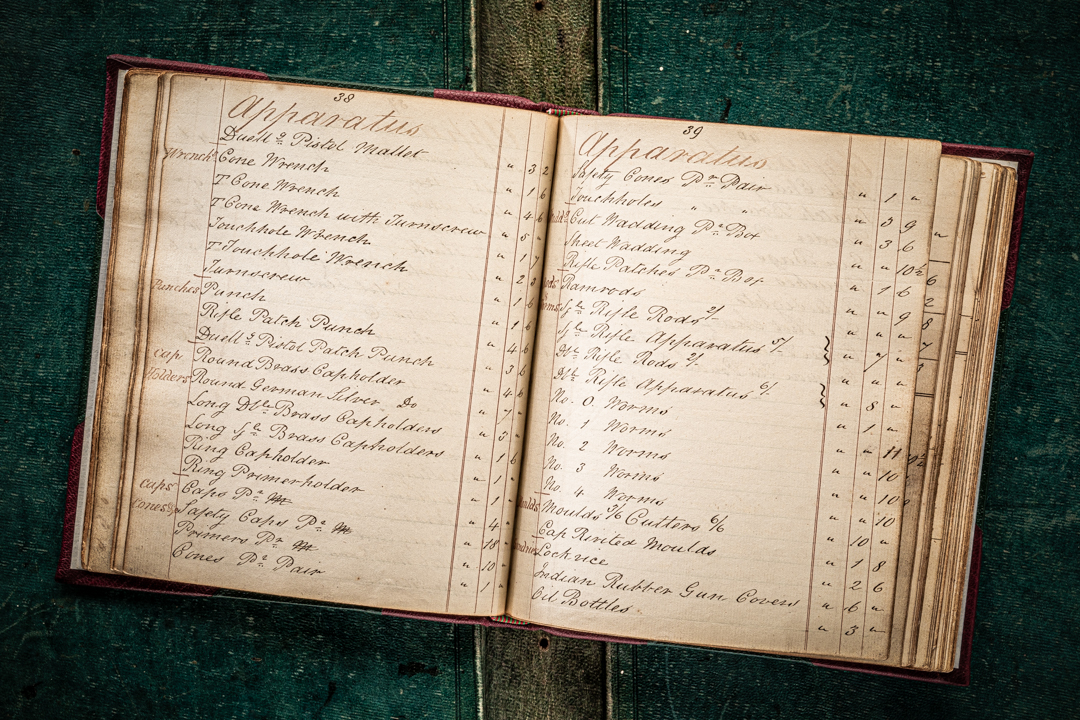

The following pages contain headings and then outline the costs of a wide range of items and labour. Items bought-in by the company include: The cost of forged barrels, locks, furniture, wadding, cases, finished guns, rifles and pistols. Firearms were, at this time, transitioning from flintlock to percussion ignition.

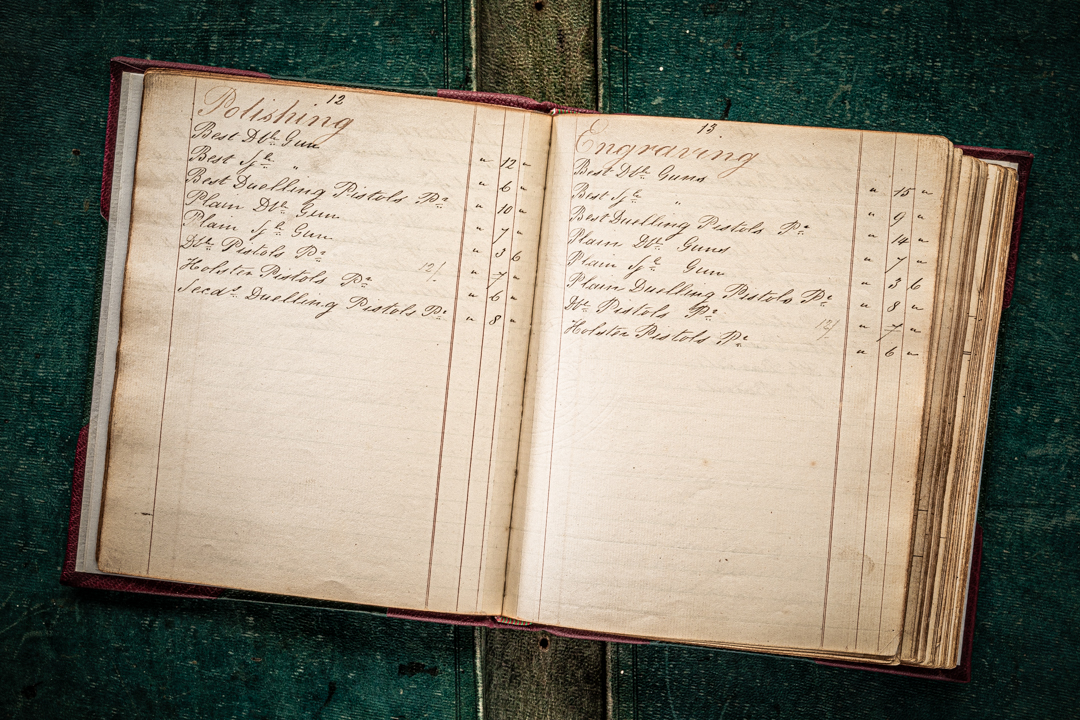

Work costs are detailed as: boring & grinding barrels, ribbing & filing barrels, stocking, fitting cocks, polishing, engraving, browning, finishing and jobbing. Finally, the retail prices charged for a full range of guns, rifles and pistols are provided.

This then, is a very useful documentation of the costs Westley Richards incurred in order to make and present for sale a wide range of products and the prices then charged to the customer in the year that Belgium first became internationally recognised as a kingdom and Lord Durham asked for permission to colonise New Zealand under the sovereignty of the United Kingdom.

Westley Richards as a company was then only in its twenty-seventh year and represented not only in Birmingham, but in London, where William Bishop was appointed agent in Bond Street in 1815. Manufacturing was clearly, at this point in time, a well regulated and organised process, meticulously costed and recorded.

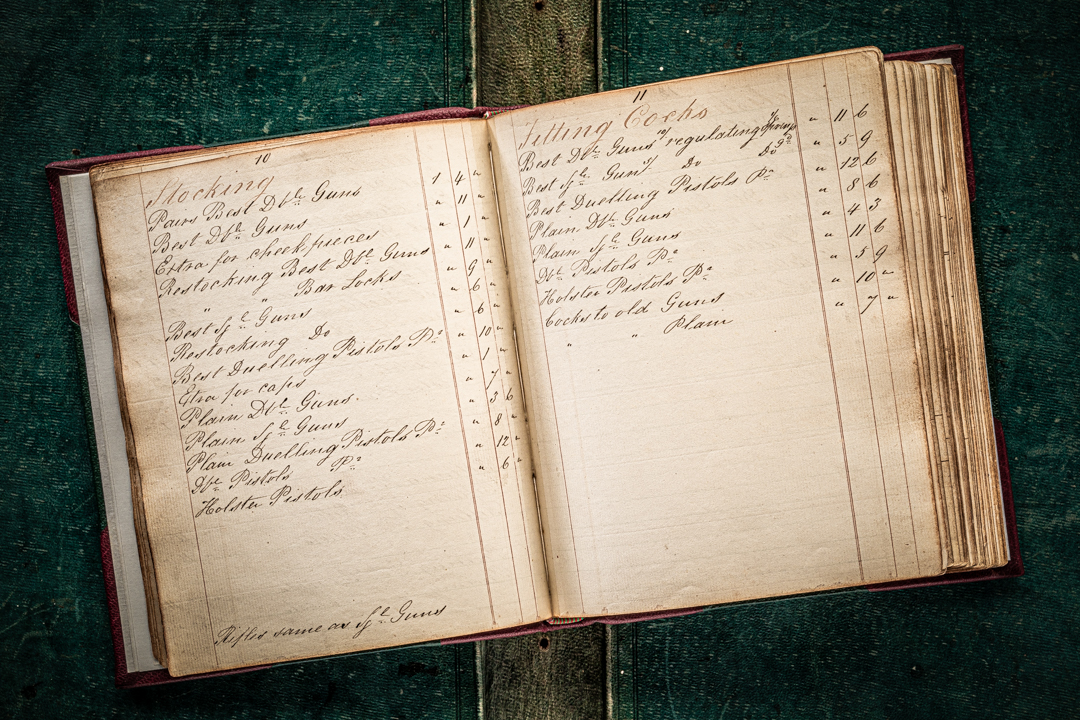

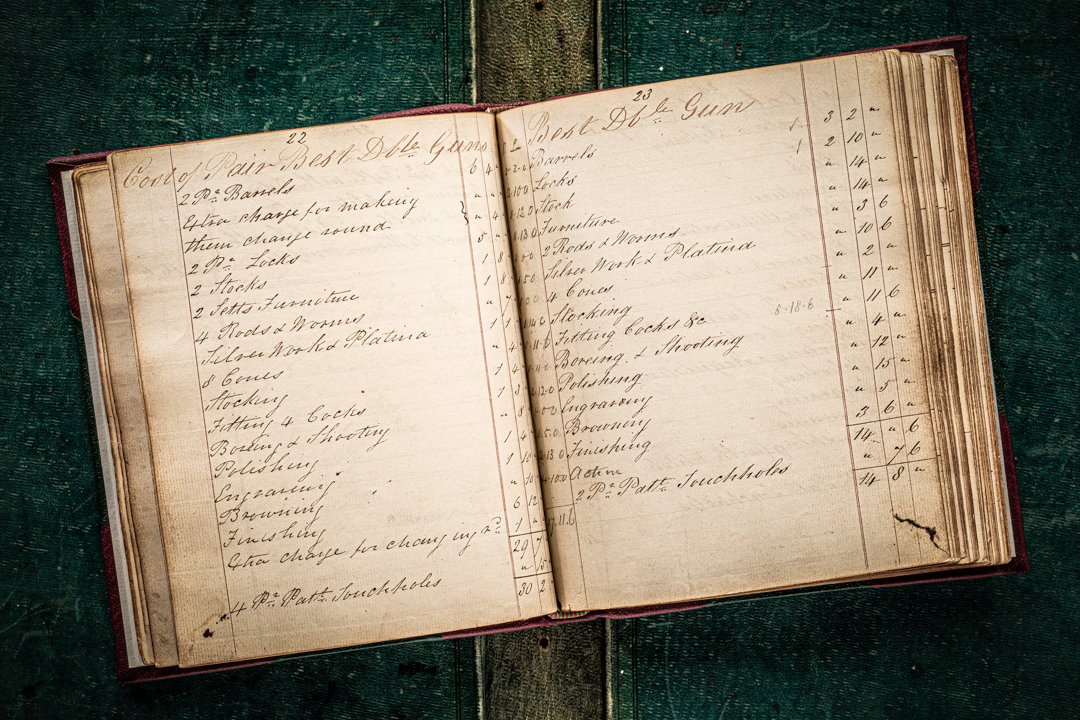

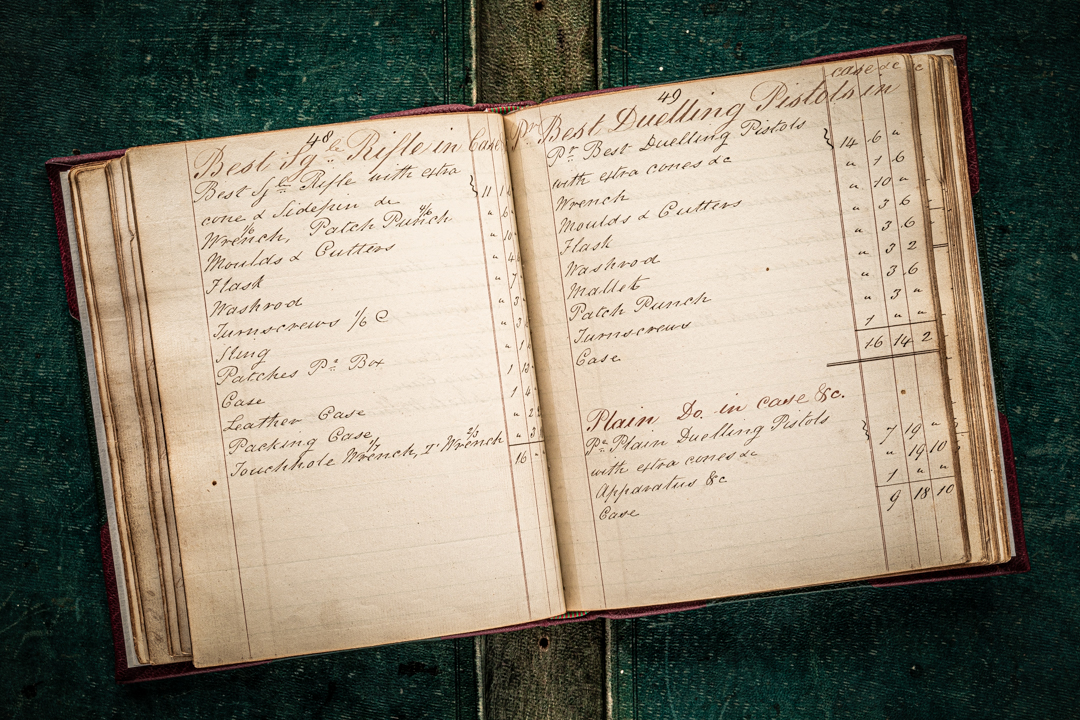

As an example of costs incurred in manufacture, a pair of forged double barrels (for rifle or shotgun) cost 20 shillings. A single barrel for a rifle cost 14 shillings and for a shotgun 12 shillings. A pair of barrels to make a pair of best duelling pistols cost 19 shillings. In common with other makers, supplying the gentry with duelling pistols was still a core part of the business until the last fatal duel in England, which took place in 1852. Duelling had, in fact, been in decline from 1844, when the British Army banned the practice. However, in 1839, when this book was penned, that ban was still five years in the future.

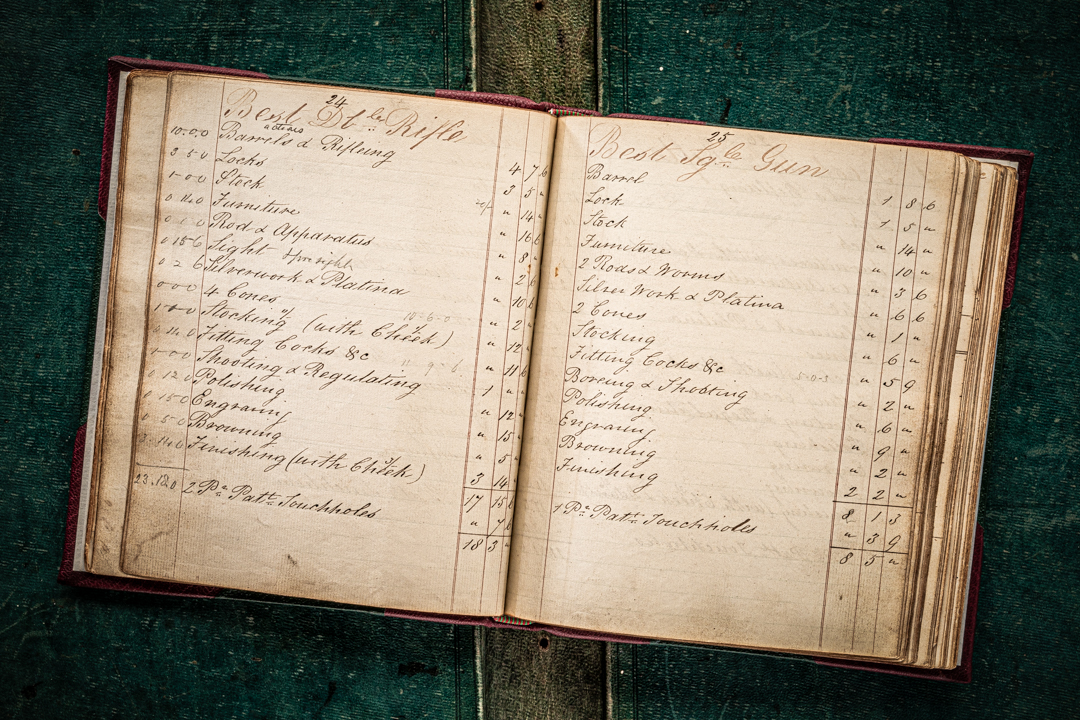

To bore and grind the barrels of a best double gun cost £1. 5.s 6d. in labour. Ribbing and filing added another £1. 8s. 0d. The full cost of a pair of ribbed and filed barrels was £3. 2s. 0d. A pair of double rifle barrels was more: £4. 7s. 0d. Once those double rifle barrels were ready, they had to be rifled at a cost of one pound and then subjected to proof at the Birmingham Proof House, which had been inaugurated in 1813, just a few miles from Westley Richards, at a cost of eleven pence.

Stocking a best double gun cost eleven shillings (£1. 4s. 0d. for a pair) and fitting and regulating the cocks to the same added eleven shillings and sixpence. Polishing a best double gun cost twelve shillings.

Gun locks for a best double gun cost £2. 10s. 0d or £3.5s. 0d for a double rifle with 'bolt & detant'. Locks for a plain double gun could be had for one pound. The furniture (guards, levers etc) for a best double gun cost fourteen shillings or sixteen for a rifle. A complete set of furniture for duelling pistols with detants cost £1. 16s. 6d.

Engraving guns today is a major part of the project, with a great deal of time and effort (and expense) applied to the matter. In 1839, there was a straightforward formula to the cost of engraving. A best double gun cost fifteen shillings to engrave. A best single barrelled gun, just nine shillings. A pair of duelling pistols cost fourteen shillings and a plain double gun, seven shillings. A pair of utilitarian holster pistols cost just six shillings to adorn with some scrolls and lettering.

To brown the Damascus barrels of that best double gun cost five shillings - a third of the cost of engraving! A single barrel cost two shillings to brown and a pair of best duelling pistols cost one shilling each to brown.

The work of the finisher in bringing every part of the gun to its full functional and aesthetic conclusion cost £3. 6s. 0d. for a best gun or £4. 0s. 0d. for a pair of duelling pistols.

The total cost of making a best double gun is given as fourteen pounds and eight shillings. That gun had a retail price of twenty-seven pounds, one shilling with an additional two pounds for accessories (flask, pouch & sling, washrod, turnscrews, brushes) and two pounds, twelve shillings and sixpence for the case.

The retail prices of the full range of Westley Richards guns, rifles and pistols in 1839 are as follow (with the cost of manufacture in brackets):

Best double guns in case (pair) £69. 0s. 0d. (Production cost £30. 2s. 0d.)

Best double gun in case £33. 13.s 0d. (cost £14. 8s. 0d)

Best single gun in case £21. 12s. 6d. (cost £8.5s. 0d)

Best double rifle in case £42.1s.6d. (cost 18. 3s. 0d)

Best duelling pistols in case (pair) £27.os.0d. (cost £14.6s. 0d)

Plain double gun in case £22.4s. 0d. (cost £8. 6S. 6d)

Plain single gun in case £12. 17s. 0d. (cost £4.16.3d)

Plain single rifle in case £16. 10.s 0d. (cost £7. 13S. 9d)

Plain duelling pistols in case (pair) £16. 0s. 0d. (cost £7. 19s. 0d)

Double pistols in case (pair) £24 0s. 0d. (cost 13. 6s. 6d)

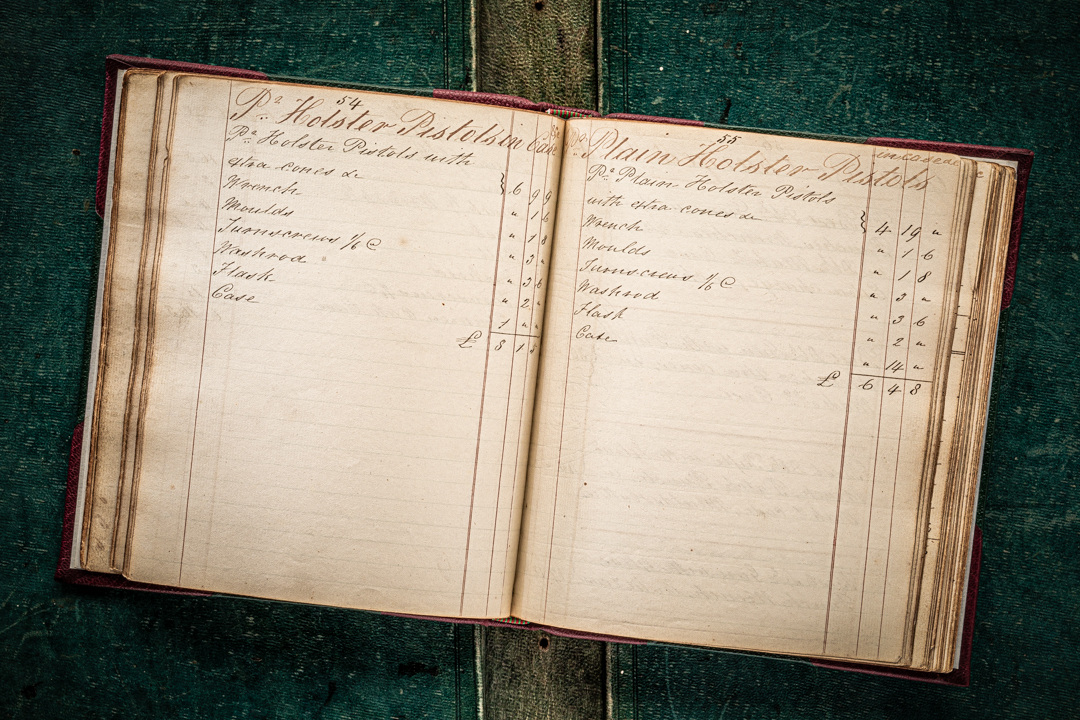

Holster pistols in case (pair) £13. 0s. 0d. (cost £6. 9s. 9d)

Plain holster pistols in case (pair) £9. 10.s 0d. (cost £4. 19s. 0d)

Cases in those days were generally made from oak or mahogany. Leather cases were options and priced accordingly, with a single case costing £1. 16s. 0d or a double £2. 10.s 0d.

As for gunsmithing services to customers, they are listed under 'Jobbing'. and include the following:

Restocking a single barrel gun cost one pound, while a double gun cost one pound ten shillings. Fitting in a pair of new barrels to a double gun also cost one pound. Cleaning a gun cost two shillings and sixpence. Fitting a mainspring cost ten shillings and lengthening a stock cost seven shillings and sixpence.

For those not familiar with the British pre-decimalisation monetary system, one pound was made up of 240 pence, or twenty shillings. One shilling was 12 pence.

For comparison with wages at the time, skilled men like stone masons and carpenters earned around 23 shillings a week, while farm labourers made only ten shillings. Inflation calculators show £1 in 1839 as equivalent to £90 in 2025. So, a best double gun made when this book was written cost the modern equivalent of £1,350 to make and sold for £1,710, which just shows how much the cost of best gun-making has increased since then. Not many carpenters are earning just £89 a week today, however, so these calculators are of very limited value. It is better to look at the cost of other goods at the time and the relationship of wages to the cost of guns.

Today, a software engineer might be the skilled equivalent of an 1830s stone mason. Software engineers earn around £110,000 a year in Britain and a best gun costs about £110,000. In 1839 the stone mason earning £55 per annum would be able to buy a best gun with eight month's wages, a software engineer today would need his full 12-months' salary.

Finally, we can turn to the pages marked 'Guns & c Charged to WB'. We can take this to mean William Bishop and the prices being those he paid as agent, allowing him a margin for profit on his London sales.

From this, we can see that Bishop (if he was selling for the same retail prices as Westley Richards in Birmingham) made nine pounds when he sold a pair of guns, three pounds when he sold a best gun and two pounds one shilling when he sold a best double rifle. He made a pound when he sold a pair of best duelling pistols. So, his commission, if he sold five best guns a month, would have been one hundred and eighty pounds per annum: more than three times the wage of a skilled man. The average wage for a working man was just thirty nine pounds a year. So, William Bishop was earning well from his role as Westley Richards' London agent.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.

Enquire

Enquire