By 1900, sportsmen had become accustomed to their breech-loading rifles and shotguns dis-assembling with ease. Magazine rifles, which were gaining popularity in the early 20th century, were unfortunately long and not so easily disassembled, therefore requiring a case at least the rifle's length. The solution Westley Richards settled upon was to cut the stock where the breech met the barrel and allow it to be detached, along with the forepart. To join the barrel to the action, a secure, reliable and stable connection was required; one that would ensure the rifle shot to point of aim every time it was re-assembled.

Our patent detachable barrel first appeared on rifles of the falling-block type. The principle was then applied to Westley Richards magazine rifles. The same lug and groove plan was used, as was the sprung-ball locator. A single pin release, activated via an external lever, allowed the barrel to be gripped in one hand, the action in the other, then a firm twist would separate them in half a turn.

A rifle built on this plan enabled it to be carried in a case the length of the barrel (typically 21" – 26") rather than the length of the rifle. This take-down system added just 2oz to overall weight. Notes in an old catalogue state, in hand-penned ink script, dated May 17th 1938: ‘…this system not now made; the lugs being replaced by the ordinary screw-thread made to be detached by hand’. The screw- thread take-down has endured ever since.

Mechanisms in the gun trade were usually altered or dropped for one of two reasons. Either they were surpassed by a better system or they were replaced with one considered equally good, or practically good enough, which was cheaper or easier to manufacture. Many early engineering solutions were brilliant and extremely robust and efficient but they were often expensive to make, requiring a lot of skilled work. Original bayonet take-down rifles had a collar onto which the lugs were formed. This was then brazed into place over the barrel to create the fixture. This brazed joint was a potential area of weakness, which the screw-thread system eliminated.

For the revived version, our team departed from this old practice and, instead, milled the lugs into the barrel itself. The point of weakness no longer exists. In terms of manufacture and assembly times, the two alternatives are very similar, now that the necessary steps have been identified and the gunmakers are familiar with the process.

New bayonet take-down rifles are available now in the classic Westley Richards chamberings of .425 and .318, in limited numbers.

Considerable research and development was devoted to perfecting the lug system, with modern modelling techniques guiding the return to traditional craftsmanship. Once completely satisfied, the manufacture of the first rifle, photographed here, was initiated and achieved through painstaking and logical rifle-building know-how.

Another departure from the original pattern is the elimination of the sprung-ball locator. The precision with which we are now able to fit the components has made it superfluous and the rifle is smoother and easier to assemble without it. The old cam-activated locking peg is replaced with our Deeley catch styled push-button release. All these subtle but important developments are indicative of our ongoing quest to refine the way our rifles work and look, without losing their old-world charm.

Foreman Stuart Richards considers the new lug system superior to the screw-thread. With it, the barrel is detached in a mere half-turn and it is faster and more convenient to operate. He is of the opinion that, with the current method of making and assembling it, the lug system no longer compromises strength or durability. It would be his choice, if pressed to select one over the other. As well as having standard iron sights, mounted on a Westley Richards quarter rib, these new rifles are fitted with a quick-detach mount system especially designed to complement the Mauser action and new take-down system.

New bayonet take-down rifles are available now in the classic Westley Richards chamberings of .425 Westley Richards and .318 Accelerated Express, in limited numbers. As with all the sporting arms we offer, each will be a bespoke build to the customer’s exact requirements.

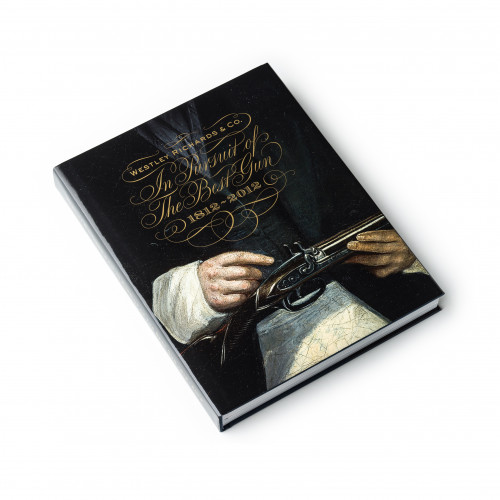

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.

Enquire

Enquire